What Is Pcb Chemical

Pcbs were manufactured domestically from 1929 until manufacturing was. Copper plating is also referred to as copper coating, copper finishing, or surface finishing.

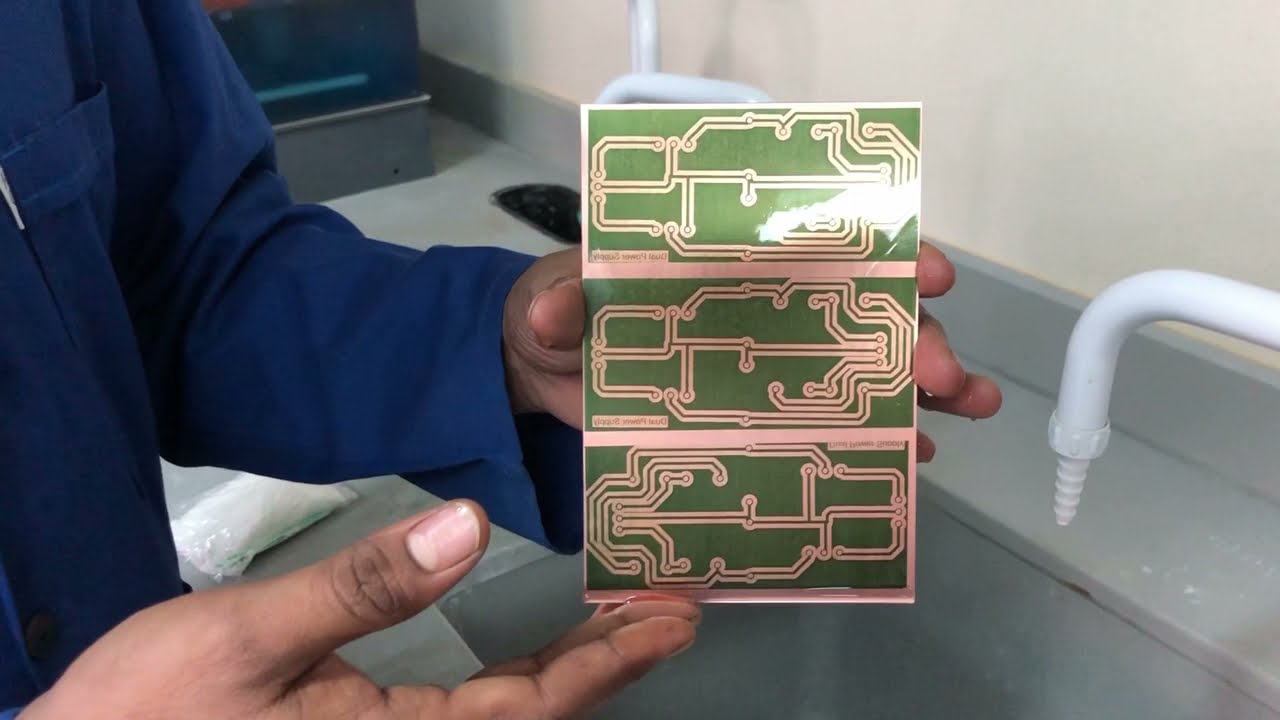

switch mode power supply Unusual chemical reaction on

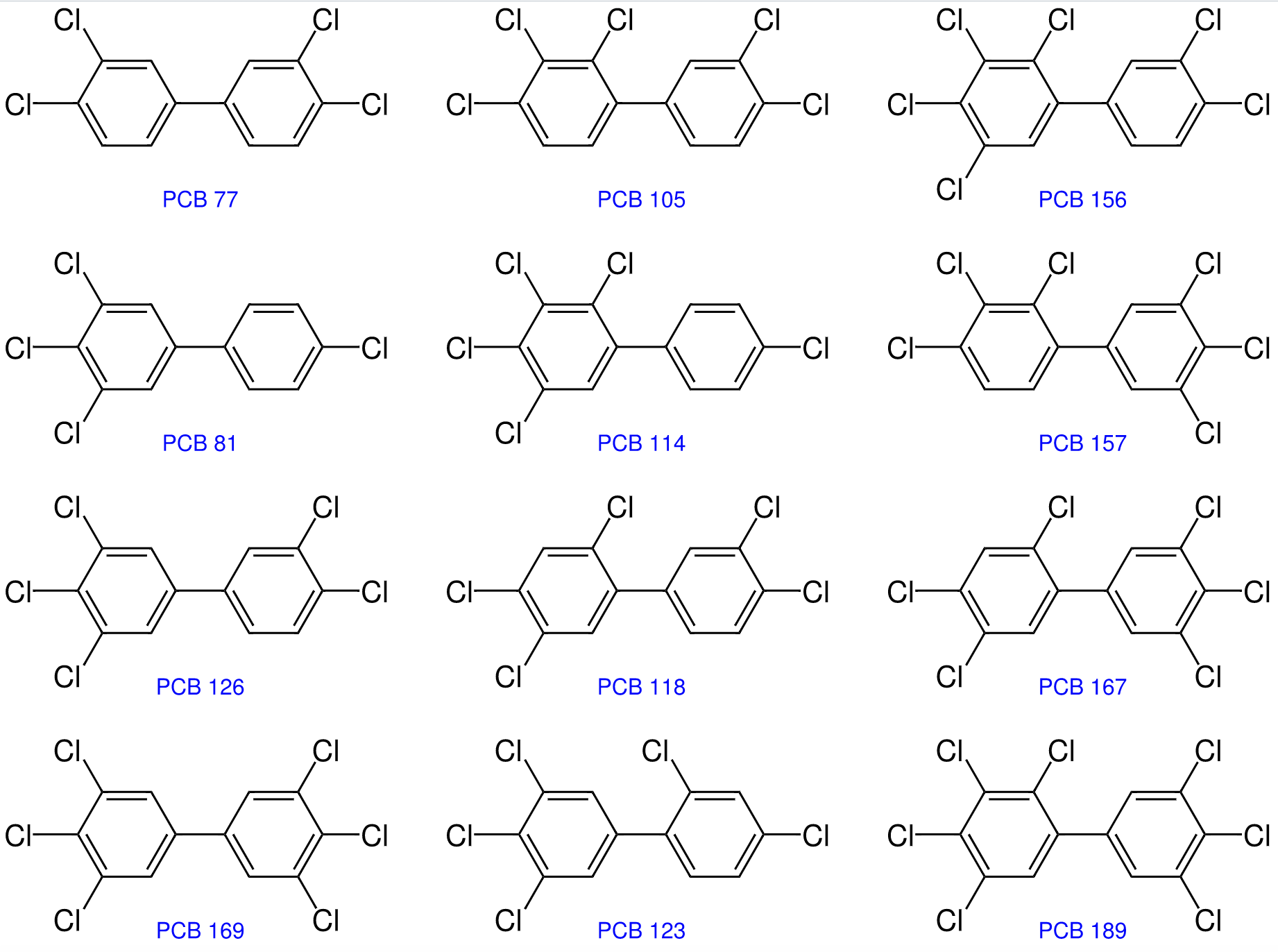

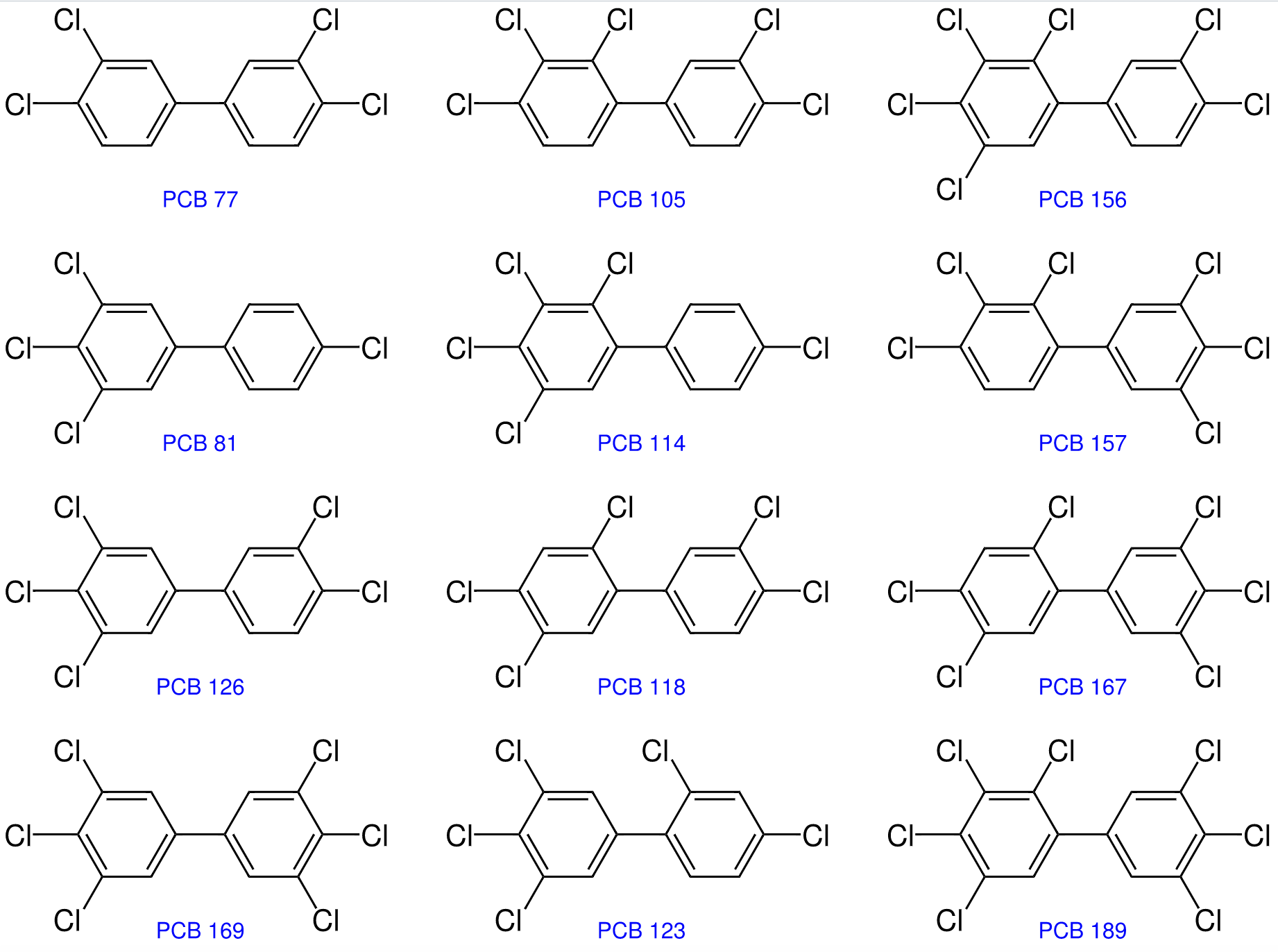

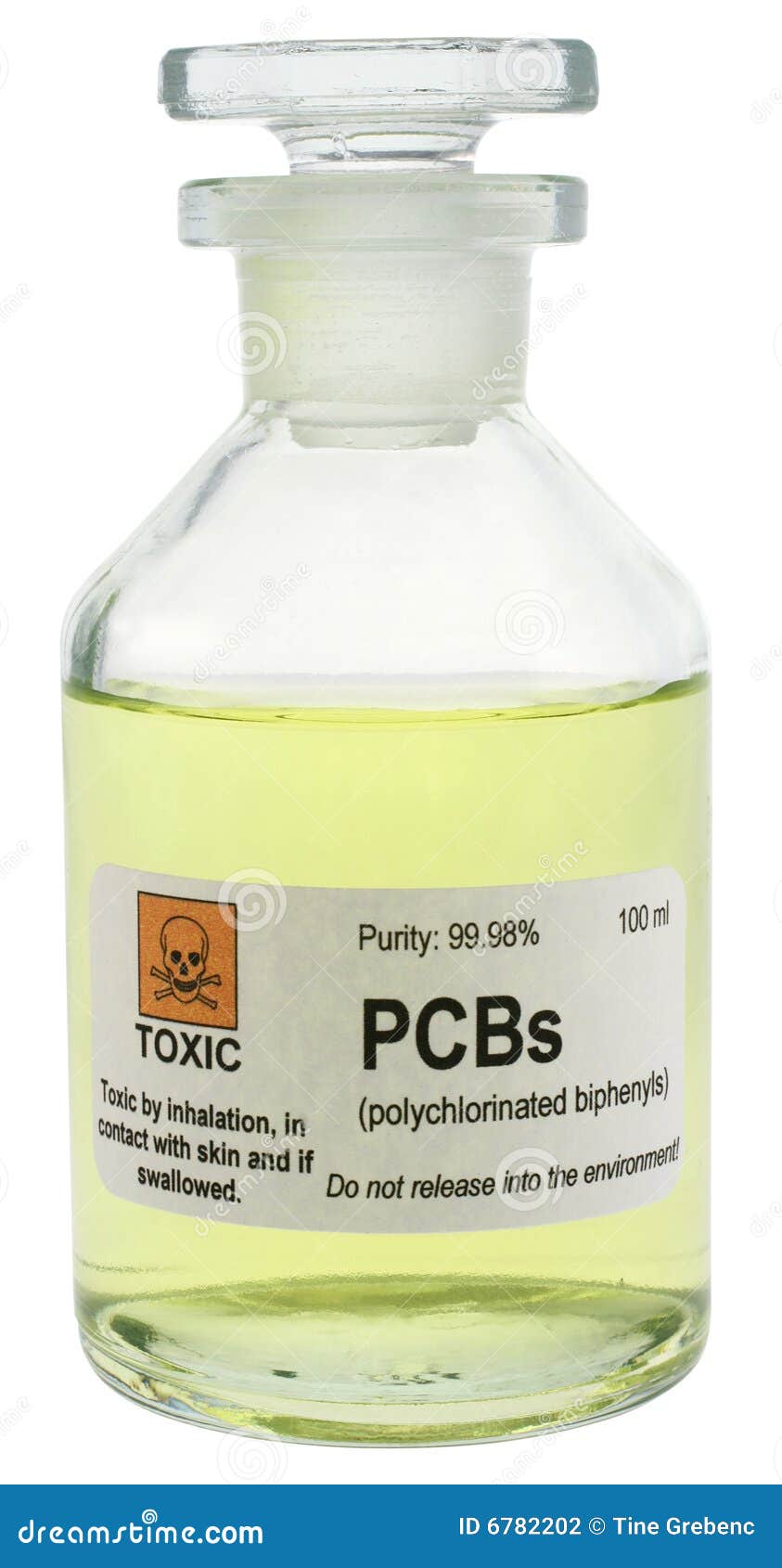

Polychlorinated biphenyls (pcb's) * comprise a class of nonpolar chlorinated hydrocarbons with a biphenyl nucleus in which any or all of the hydrogen atoms have been replaced by chlorine.

What is pcb chemical. Much denser than water and insoluble in water. Polychlorinated biphenyls (pcbs) are industrial chemicals that were manufactured from 1929 until 1979 when they were banned. Polychlorinated biphenyls are a group of 209 different chemicals which share a common structure but vary in the number of attached chlorine atoms.

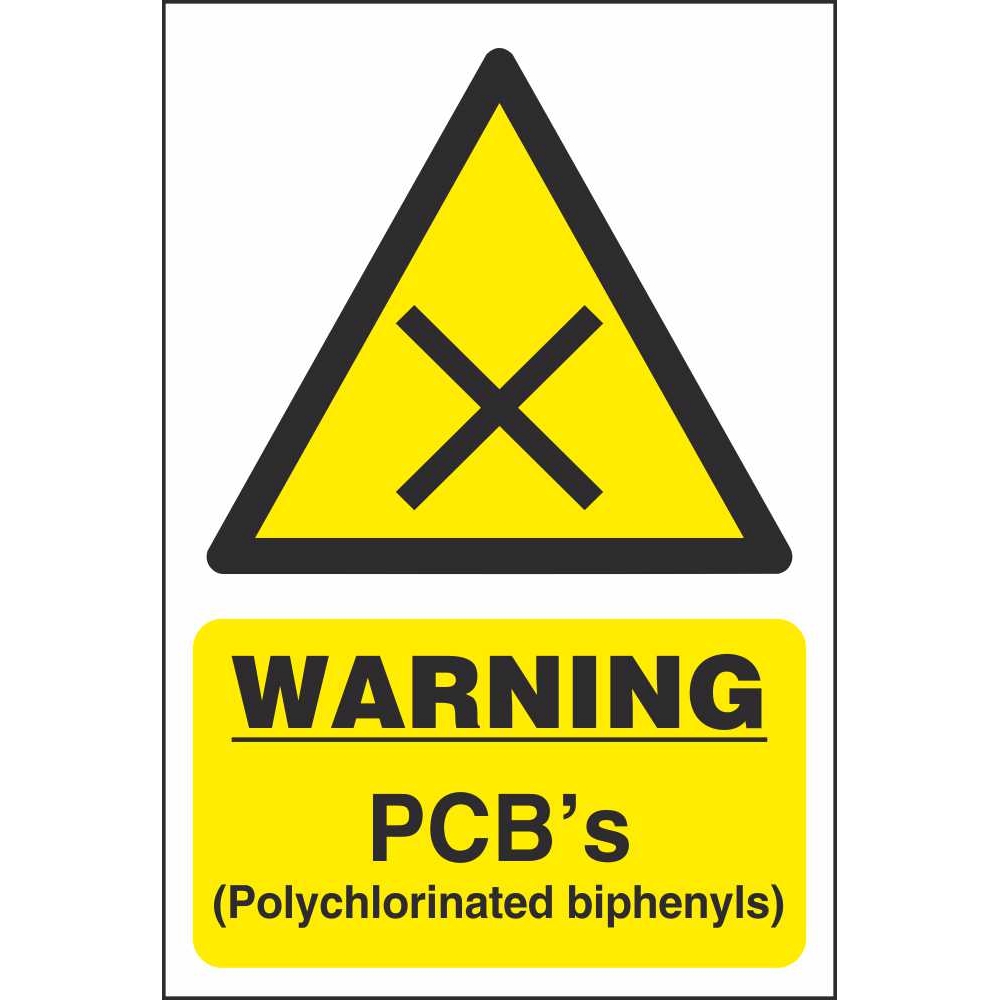

Pcb contamination is high in the housatonic river and new bedford harbor in massachusetts. What are the human health effects of pcbs? Pcbs have been shown to cause adverse health effects, including potential cancers, and negative effects on the immune, nervous and endocrine systems.

Chemical pcb abbreviation meaning defined here. In pcbs, chlorine atoms replace some of these hydrogen atoms. The name of a congener specifies the total number of chlorine substituents and the position of.

Plating chemicals are used to protect exposed copper and prep the materials for the soldering process. In this passage, we will focus on the chemical solution used in pcb etching. In pcb making concentrated hydrochloric acid or concentrated nitric acid is used for etching process.

Copper plating is also referred to as copper coating, copper finishing, or surface finishing. The general chemical structure of chlorinated biphenyls is shown below. Check and read for more.

Table of polychlorinated biphenyl (pcb) congeners. Please check and read to learn more. Some pcbs are volatile and may exist as a vapor in air.

Pcbs are either oily liquids or solids and are colorless to light yellow. Pcbs are a group of synthetic organic chemicals that can cause a number of different harmful effects. The second is to provide reliable electrical connections (and also reliable open circuits) between the component's terminals in a.

At present, the means to process a pcb is through model plating. Polychlorinated biphenyls commonly known as pcbs are man made chemicals that never existed in nature until the 1900's when they started to be released into the environment by manufacturing companies and consumers. Due to the mixed chemical nature of the exposure, the results cannot be attributed solely to pcbs [atsdr 2000].

What does pcb stand for in chemical? They have no known smell or taste. Pcbs have two complementary functions.

1 commercial pcb's are mixtures of isomers of chlorinated biphenyls exhibiting varying. Pcbs are a group of chemicals that have extremely high boiling points and are practically nonflammable. This is done to help combat oxidation as well.

This will remove unwanted copper. Get the top pcb abbreviation related to chemical. Monochlorinated biphenyls (i.e., one chlorine atom attached to the biphenyl molecule) are often included when describing pcbs.

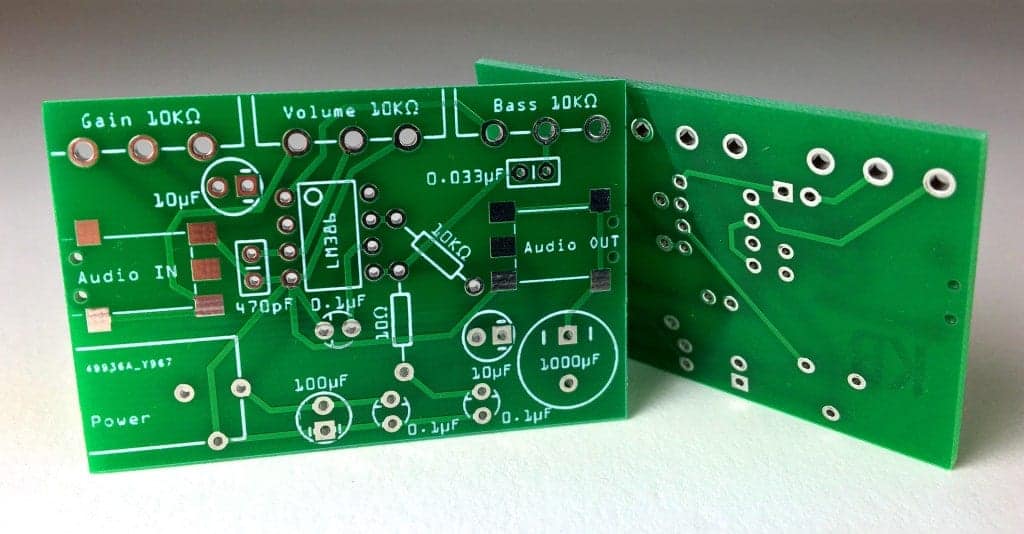

A printed circuit board (pcb) is a laminated sandwich structure of conductive and insulating layers. Pcb containing equipment, materials, and oils were regularly managed without sufficient care causing personnel and environmental exposures. May burn under exposure to intense heat or flames for prolonged periods of time.

An estimated 1.3 million pounds of different types of pcbs were dumped into the hudson river by general electric from 1946 until 1977, when they were banned. In the modern process, these unwanted removed copper is collected in a drum and is recycled for copper plating. Pcbs can pose serious health risks to people who frequently eat contaminated fish.

Printing a pcb on a flat metal piece to unveil line design is a complex process of visual and chemical charge. There are no known natural sources of pcbs in the environment. This is done to help combat oxidation as well.

Liver damage is a consistent and prominent finding among animals exposed to pcbs, particularly rats and monkeys, which are the species tested most extensively. There are many chemicals used in pcb manufacturing Printed circuit board (pcb) chemicals rbp chemical technology is a leader in developing chemistry for pcb fabrication and supplying leading electronics manufacturers worldwide.

Pcbs, or polychlorinated biphenyls, are industrial products or chemicals. The first is to affix electronic components in designated locations on the outer layers by means of soldering. Each pcb molecule contains two phenyl rings.

Pcbs are colorless oily liquids. A phenyl ring is a ring of 6 carbon atoms to which hydrogen atoms are attached. This implies adding a lead tin resistant to the surface layer in.

Plating chemicals are used to protect exposed copper and prep the materials for the soldering process. Polychlorinated biphenyls (pcbs) were developed in the 1940's and were used extensively in the manufacture of transformers, capacitors, and other heat transfer devices through the late 1970's.

Etching process PCB manufacturing chemical process YouTube

![]()

PCBs Free Icon. Polychlorinated Biphenyls Chemical

PCB Conformal Coating Venture Elctronics

PCBs Chemical Warning Signs Dangerous Goods Safety Signs

What are Polychlorinated Biphenyls (PCBs)?

PCB platform for monitoring of chemical reactions. The

How to Design a PCB Layout Circuit Basics

Preventing Critical PCB Contamination There Goes the Boom

PCB Manufacturing USA PCB Design Service Electronic

Buy The Safest Chemicals For Your PCBs electronicsb2b

What Chemicals Are Used in PCB Manufacturing? SVTronics Blog

Circuit Board Builder what is pcb chemical

PCBs, the infamous chemicals harming the environment

PCBs stock photo. Image of biphenyl, concept, laboratory

Monsanto Given Legal Shield in a Chemical Safety Bill

Chemical structure of PCBs under study. Download